New racing beast for Richard Mille with Ferrari

Today, we're diving into the world of fine watchmaking with a piece that packs a punch: the RM 43-01 Ferrari Tourbillon Split-Seconds Chronograph. A second collaboration between Richard Mille and Ferrari, it's simply incredible. Here again, the two brands are on a par with the exceptional, to the delight of aesthetes who love high technology.

Two legendary brands, two drivers at the top of their game, two incredible variations… the new Richard Mille RM 43-01 watch, developed with Ferrari, is full of superlatives.

Be careful, it’s brutal, powerful, extraordinary, and yet, we are in the realm of the infinitely small!

This watch is the marriage of two legendary brands, two brands that worked together from the beginning of the design to the model’s release. Richard Mille production specialists will have noticed that the case benefits from “aerodynamic” improvements: Ferrari engineers have been there.

The 42.9 mm wide, 51.2 mm long and 17.1 mm thick tonneau case is available in two versions limited to 75 pieces each: one in microblasted and polished grade 5 titanium, with a Carbon TPT® caseband, the other entirely in Carbon TPT®, the carbon exclusive to Richard Mille. You could say: the titanium model for the gentleman driver, carbon for the racing driver. Driving a Ferrari? Not only that…

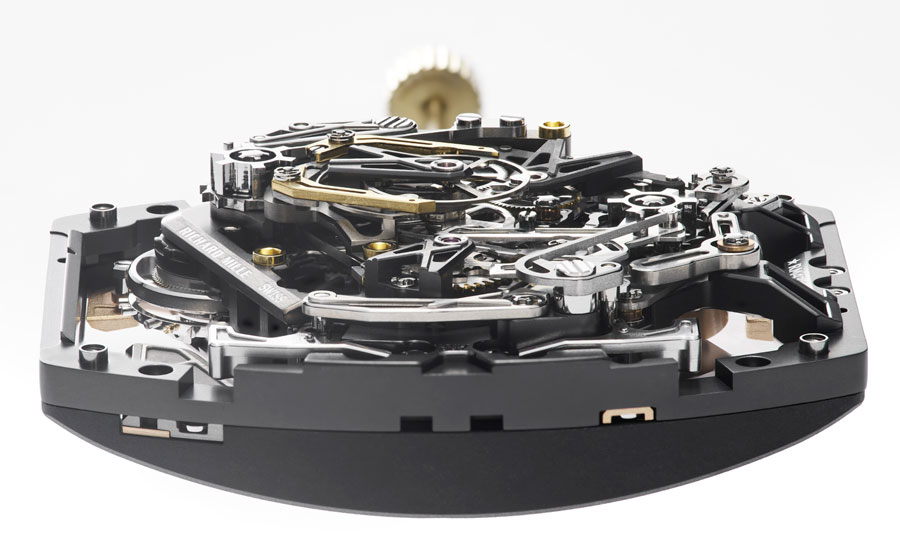

Under the hood, we find the hand-wound RM43-01 caliber. It displays hours, minutes, a tourbillon, a split-seconds chronograph with double column wheels, a 70-hour power reserve, a torque indicator, and a selection function for the crown: winding (W), time setting (H), neutral (N). A bit like a gearbox!

In terms of design, every detail reflects the Ferrari spirit. The crown, hands, and bracelet are inspired by the Purosangue. The openworked movement reveals a titanium plaque with the prancing horse logo, reminiscent of the 499P’s rear spoiler. The pushers are inspired by the SF90 Stradale’s taillights.

The finishes are uniform, extremely meticulous, and alternate between microblasting, satin-finishing, and polished angles. A true work of master watchmaking.

With a water resistance of 50 meters, it will easily withstand champagne showers on the top step of the podium, but avoid extreme water sports. A fall, as we know, can generate pressure exceeding 10 bars, and we wouldn’t want this marvel to take on water.

In short, the RM 43-01 Tourbillon Chronograph Split-Seconds Ferrari is the perfect alliance between Richard Mille’s watchmaking engineering and Ferrari’s automotive design.

Well, obviously, the price is a “grand prix”… Formula 1 requires it.

RM 43-01 Tourbillon Split-Seconds Chronograph Ferrari – Titanium – Limited edition of 75 pieces – CHF1,150,000 CHF (excl.tax)

RM 43-01 Tourbillon Split-Seconds Chronograph Ferrari – Carbon TPT® – Limited edition of 75 pieces – CHF1,350,000 CHF (excl.tax)

Of course, it’s expensive, very expensive even. But it’s top-flight technology! It’s no different at Richard Mille and Ferrari.

Read the specifications below and you’ll understand why…

Manual winding tourbillon movement with:

• Hours, minutes, seconds

• Split-seconds chronograph

• 30-minute totalizer

• Power reserve

• Torque and function indicators

MOVEMENT DIMENSIONS

31.20 x 36.45 x 7.47 mm

BALANCE WHEEL DIAMETER

10.00 mm

JEWELS

43

BALANCE WHEEL

Glucydur®, 2 arms, 4 setting screws, moment of inertia 10 mg•cm2, angle of lift 53°

FREQUENCY

21,600 vph (3 Hz)

BALANCE SPRING

elinvar by Nivarox®

SHOCK PROTECTION

POWER RESERVE

Around 70 hours (±10%), without chronograph running. Actual power-reserve results will depend on the period of time the chronograph is utilised.

SKELETONISED GRADE 5 TITANIUM BASEPLATE

The baseplate has been finished in grade 5 titanium, a biocompatible, highly corrosion-resistant and remarkably rigid alloy, which enables the gear train to function effortlessly. The alloy is 90% grade 5 titanium, 6% aluminium and 4% vanadium. This combination further increases the mechanical properties of this material, which explains its frequent use in the aerospace, aeronautics and automotive industries.

BRIDGES IN GRADE 5 TITANIUM AND CARBON TPT®

The titanium bridges have been skeletonised as far as possible to reduce the total weight of the calibre. This feat was also achieved through the incorporation of cutting-edge materials such as Carbon TPT®, used for some bridges of the split-

seconds chronograph.

These technical solutions give this complex calibre—with its extreme weight to resistance ratio—an impressive resistance capacity, tested in our workshops to shocks of over 5,000 g, a prowess for a watch combining a tourbillon escapement and a complex split-seconds chronograph mechanism.

SPLIT-SECONDS SYSTEM

The RM43-01 is equipped with the latest-generation split-seconds mechanism developed by Richard Mille and APLL (Audemars Piguet Le Locle).

Two 6-column wheel operates the different levers of the split-seconds function and optimises the chronograph’s operation. It ensures optimised simultaneous movement, maximal function locking, and greater adjustment durability. In-depth studies carried out on the function of clamps also led to a specific clamp design. The traditional helical spring is replaced by a blade on the split-seconds wheel, a technical decision that reduces the variation in torque when the split-seconds function is activated. All of these developments considerably improve the timekeeping performance and halve the chronograph’s energy consumption by reducing arbor friction.

FUNCTION INDICATOR

In a manner similar to a car’s gearbox, the function indicator allows one to see the winding, neutral and hand-setting positions as the crown is pulled out. The active position is indicated via a hand at 4 o’clock pointing to the following functions: W (Winding) – N (Neutral) – H (Hands).

TORQUE INDICATOR

This indicator supplies information about the mainspring’s tension, thus permitting an optimisation of the chronometric functioning of the movement.

FREE-SPRUNG BALANCE WITH VARIABLE INERTIA

This type of balance wheel guarantees greater reliability when subjected to shocks and during assembly or dismantling of the

movement, thus providing better chronometric results over time. The index is eliminated, thereby allowing a more precise and repeatable calibration using 4 setting screws.

FAST-ROTATING BARREL (6 HOURS PER REVOLUTION INSTEAD OF 7.5 HOURS)

This type of barrel provides the following advantages:

• The phenomenon of periodic internal mainspring adhesion is significantly diminished, thereby increasing performance.

• Provision of an excellent mainspring delta curve with an ideal power reserve/performance and regularity ratio.

WINDING-BARREL TEETH AND THIRD-WHEEL PINION WITH CENTRAL INVOLUTE PROFILE

The central involute profile of the winding-barrel teeth provides an optimal pressure angle of 20°, which promotes effective rotary motion and compensates for possible variations in the operation of the going train. This, in turn, ensures excellent torque transmission and a distinct improvement in performance.

BARREL PAWL WITH PROGRESSIVE RECOIL

This device permits an appreciable winding gain (around 20%), especially during the start of winding. It is also helpful in ensuring an even distribution of the mainspring’s internal tension.

SPLINE SCREWS IN GRADE 5 TITANIUM FOR THE BRIDGES AND CASE

The design of these screws permits better control of the torque applied during assembly. These screws are therefore unaffected by physical manipulation during assembly or disassembly and age well.

MOVEMENT

• Hand-polished bevelling

• Hand-polished locking sections

• Sapphire-microblasted milled sections

• Lapped and polished contact points

• Burnished pivots

STEEL PARTS

• Wire-drawn and microblasted surfaces

• Hand-polished beveling

WHEELS

• Concave chamfering with a diamond tool

• Circular-decorated front faces

• Rhodium plating (before cutting the teeth)

• Minimal corrections applied to the wheels in order to preserve geometry and performance.

CASE

The design and execution of the watch demonstrate a holistic approach to conception of the movement, case and dial. As a result, everything has been constructed according to extremely rigorous specifications. For example, a casing ring is no longer used, and the movement is mounted on chassis mounting rubbers (ISO SW) fixed by titanium screws.

Carbon TPT® version

Carbon TPT® is a remarkable material with a unique finish. It is obtained by layering hundreds of sheets of carbon fibres (with a maximum thickness of 30 microns), by using an automated process that changes the orientation of the weft between layers. Heated to 120 °C at a pressure of 6 bars in an autoclave similar to those used for aeronautic components, the material is then ready to be machined at Richard Mille to create the case and its pushers.

Titanium version

The bezel and caseback are made of grade 5 titanium whilst the caseband and pushers are made of Carbon TPT®.

The bezels are microblasted with hand-polished bevels.

The tripartite case is water resistant to 50 metres, ensured by 2 Nitrile O-ring seals. The case is assembled with 20 grade 5 titanium spline screws and abrasion-resistant washers in 316 L stainless steel.

DIMENSIONS

42,90 x 17,10 x 51,20 mm

TORQUE LIMITING CROWN

This added security system prevents accidental overwinding of the watch, the result of which can cause damage such as

breaking the winding stem or putting too much pressure on the barrel spring.

DIALS

In satin-finished and microblasted grade 5 titanium, with hand-polished bevels.

UPPER FLANGE

In microblasted titanium with black galvanic treatment.

BEZEL AND CASEBACK

Bezel side

• Sapphire crystal (1,800 Vickers) with anti-reflective treatment (on both sides).

• Thickness: 1.50 mm

Caseback side

• Sapphire crystal with anti-reflective treatment (on both sides).

• Thickness: 1.00 mm

Limited edition of:

• 75 pieces in Carbon TPT®

• 75 pieces in titanium and Carbon TPT®

See also:

Read also: