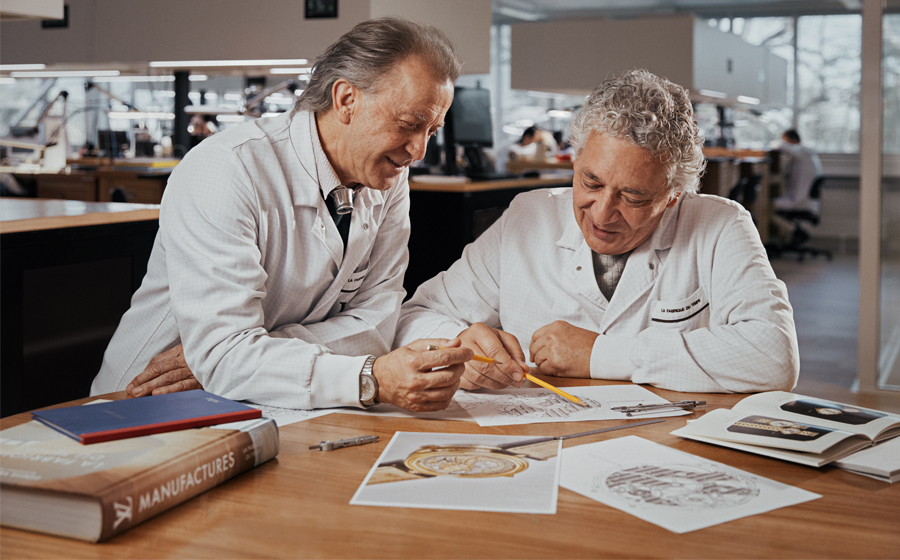

Meeting with the craftsmen of the Fabrique du Temps Louis Vuitton

Enamelers, engravers, jewelers, guillocheurs, miniature painters… In Meyrin, Switzerland, the master craftsmen of the Fabrique des Arts Louis Vuitton reveal their exceptional expertise to Frank Sans C in a breathtaking program. Enhanced by the explanations of Michel Navas, the master watchmaker and co-founder of the Fabrique du Temps, this exclusive immersion opens the doors to a world where tradition and innovation rub shoulders with excellence. A true temple of artistic crafts, the Fabrique du Temps Louis Vuitton is the marriage of ancestral gestures and exceptional creation. A marriage dedicated to resolutely contemporary fine watchmaking.

The Fabrique des Arts at the heart of the Fabrique du Temps Louis Vuitton

Masterfully orchestrated by the two famous watchmakers Michel Navas and Enrico Barbasini, the Fabrique du Temps Louis Vuitton houses at its heart all the crafts necessary for the creation of its iconic timepieces.

Like the various cogs that make up a movement and ensure its proper functioning, this manufacture has integrated, since 2023, specialized workshops, from the production of each component, through assembly and ornamentation. Thus, the Fabrique des Boîtiers, the Fabrique des Mouvements and the Fabrique des Arts work together to create watchmaking marvels, illustrations of the remarkable know-how of the Louis Vuitton house, which combines artisanal transmission and the use of avant-garde technologies.

Let us focus here on the Fabrique des Arts, which brings together five exceptional sectors – guillochage, enamelling, engraving, jewellery and miniature painting – and brings together the “cream of the crop” of artisans, true masters in their field.

Enameling or the art of the second

“Paillonné”, “champlevé”, “cloisonné”, plique-à-jour”, “grisaille”, these sweet-sounding words designate the different enameling techniques carried out by the four enamelers working within the factory. Like Nicolas, who explains all the stages of this process so complex to master. He has been practicing this trade for around fifteen years and is still learning the subtleties of this fascinating profession.

After first mixing the enamel crystals with demineralized water to obtain a smooth and homogeneous powder, he proceeds to crush these crystals using a pestle. In order to obtain perfectly regular grains, he lets himself be guided by the rhythm of a metronome which punctuates his gesture like a conductor.

The artisan also insists that it’s best to change hands to avoid tiring and to rotate in both directions to avoid missing any grain. Consistency in grinding is a fundamental step: “It’s the rigor that ensures the consistency of the grains, the time is calculated to the nearest second,” Nicolas insists. A second that can also prove crucial during the cooking stage.

Depending on the grain size and the thickness of the layer, several passes are necessary, ranging from twenty to forty, sometimes more. The further you advance in the firing of the piece, the more essential it is to have a temperature adjusted to the nearest degree. Here, everything is still a matter of seconds, because the enamel must melt without dissolving into the material. A true alchemy in short, “a feeling where you don’t have to question the fundamentals of the technique,” explains Nicolas.

Tambour Fiery Heart Automata Louis Vuitton: of glass and fire

Equipped with the first in-house self-winding automaton movement, the Tambour Fiery Heart Automata is a distillation of watchmaking expertise

The Tambour Fiery Heart Automata watch incorporates the ancestral know-how of grand feu enameling. This technique consists of applying a silica powder mixed with metal oxides, then firing it at a very high temperature (between 700° and 1,200°C), resulting in a vitrified material with intense and lasting colors. The dial combines two methods: champlevé enameling, where the enamel is inserted into cavities carved into the metal, and cloisonné enameling, which uses very fine gold wires to outline patterns that are then filled with enamel. This blend of refined techniques gives the piece an artistic and very realistic character. Price on request.

Louis Vuitton Voyager Flying Tourbillon Poinçon de Genève Plique-à-jour: another stopover in the art of enameling

Next stop in the exploration of enameling with the plique-à-jour technique on this Voyager Flying Tourbillon Ponçoin de Genève Plique-à-jour.

The enameler used the traditional capillary technique, applying the color with a brush in open cells with lightness and precision. This method allows for uniform enameling, without air bubbles. On this piece, it reveals unique transparency effects. The white gold dial, adorned with Vuitton’s interlaced V, showcases ultra-luminous plique-à-jour enamel. The central gradient at 12 o’clock, composed of three blues—ultramarine, azure, and bluish-gray—accentuates the visual richness of the dial, like a miniature stained-glass window. Price upon request.

Engraving or the art of dexterity

Head to the workbench of Noé, master engraver at the Fabrique des Arts, who is busy engraving the dragon featured on the dial of the Escale Cabinet of Wonders Dragon’s Cloud watch, part of the triptych created in homage to Gaston-Louis Vuitton. Price upon request.

First, the craftsman makes a specific tool according to the engraving requirements, as everything depends on the type of ornament to be made. It is also essential to take into account the angle at which the instrument is sharpened.

Indeed, it is a detail that is not ultimately one, it is an essential factor in the execution of the work in progress. The pressure, which is controlled, is also to be taken into account depending on the depth to be reached. Here, the dragon is shaped in gold, because it is the most ductile material, therefore “engravable” according to “the delusions of artists”. Price on request.

Consult the technical sheets of the Louis Vuitton Escale – Cabinet of Wonders – Dragon’s Cloud, the Louis Vuitton Escale – Cabinet of Wonders – Koï’s Garden et the Louis Vuitton Escale – Cabinet of Wonders – Snake’s Jungle.

Jewelry or the art of illusion

The master jeweler is one of the essential links in this artistic and technical chain. Lise is responsible for polishing the small mother-of-pearl beads that will be affixed to the dial of the Escale Cabinet of Wonders Koï’s Garden watch. They will represent the pebbles in the carp pond.

The mother-of-pearls are recovered from the digital machining process and then finished by the jeweler, who will satin-finish and polish them. To begin, she will glue them onto a small boxwood stick. Then, using erasers, she will delicately remove the machining marks, then polish with polishing paste and rub to give them all their shine. Once this work is done, they are turned inside out, where a layer of white paint is applied to bring out their color.

Note that the fineness of the mother-of-pearl is such that it is possible to put any shade of paint on the back, as well as different patterns, in order to create a relief, such as the illusion – on this watch – of the presence of water at the bottom of the dial. The next step will be to assemble them on the dial.

Still at the jewelry store, but this time heading to Damien’s workbench, whose task is to re-wrap the metal around the enamel and polish it. Indeed, when it comes out of the oven, a phenomenon called “scale” is deposited on the material.

With a micro-polishing tool and a slightly abrasive eraser, the gold surrounding the enamel is restored to restore all its shine.

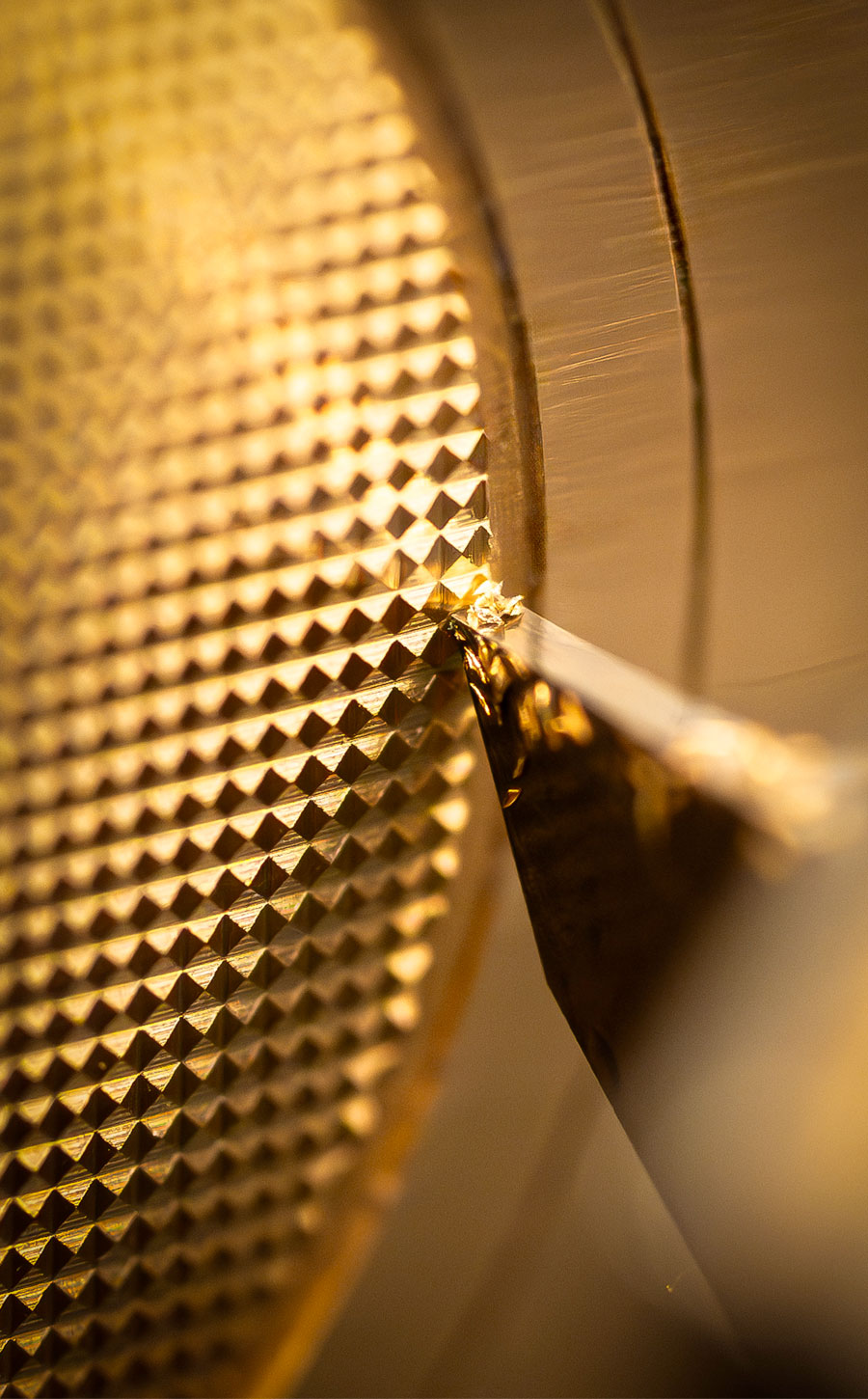

Guilloché or the art of regularity

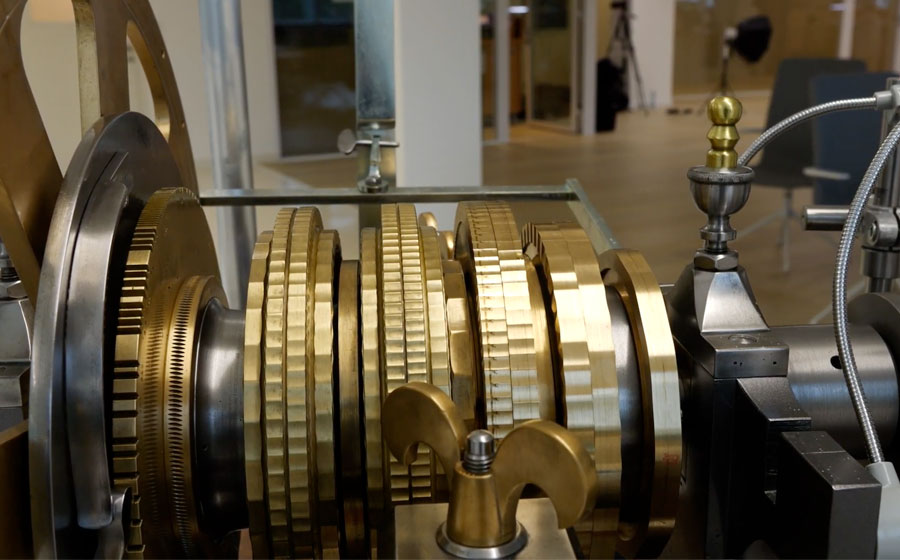

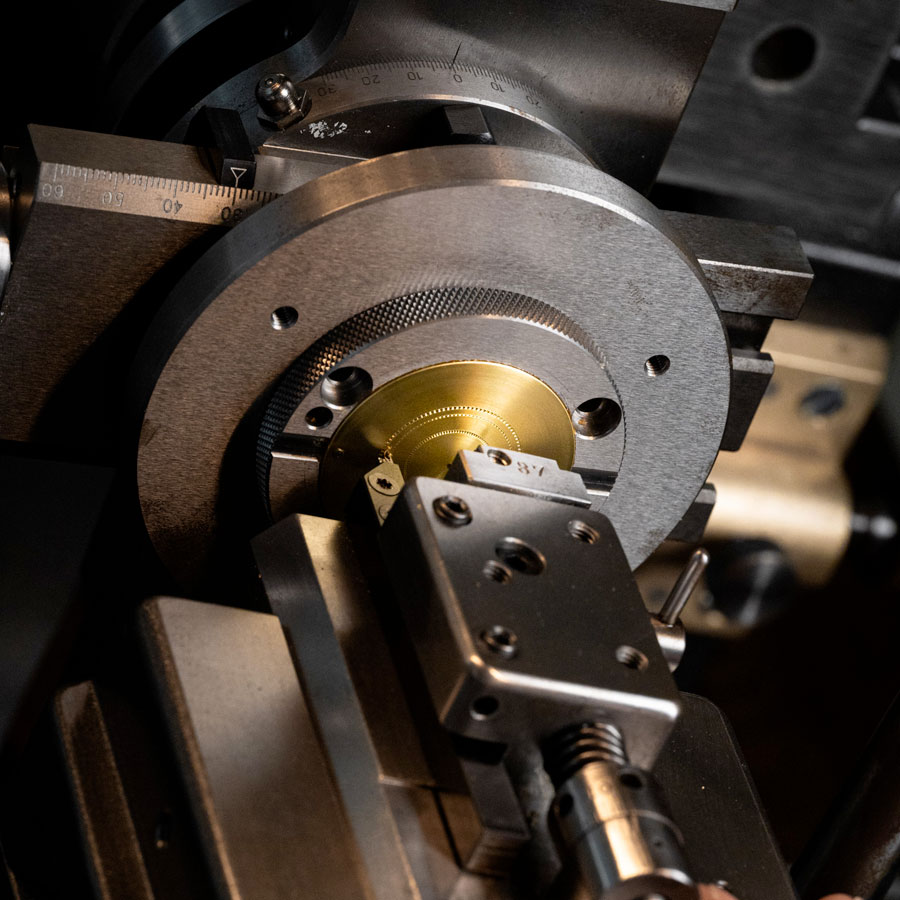

At Louis Vuitton, it is essential to have a guilloché workshop that meets the aesthetic demands and expectations imposed by the Fabrique du Temps. There are five guilloché machines in the workshop, masterfully orchestrated by Koray, head of the Fabrique des Cadrans and the Fabrique des Arts.

As a side note, he was commissioned to find the 1850 guilloche lathes and was tasked with their restoration. This guilloche lathe was entirely guilloché by the Fabrique du Temps.

It has all the features of a guilloche lathe, namely numerous rosettes, in other words a set of cams which will provide the decorations for the different guilloche patterns (barley grains, rice grains, skipped lines, waves, etc.).

It should also be noted that the five machines have their specificities: circular lathes; linear lathes such as the “lignes” or the “Clous de Paris”; the upholstery or engraving machine. The presence of so many devices is justified by the importance given to the decoration of the calibers and the finishing of the dials, which is at the center of all concerns, in the same way as the other components of the watch.

Miniature painting or the art of high-flying “coloring”

Miniature painting techniques are showcased in the Escale Worldtime watch. It perpetuates the great tradition of travel cherished by Louis Vuitton. With its artistic dial, the piece evokes the Maison’s famous trunks, personalized with colored bands, initials, coats of arms, and other geometric pictograms that travelers used to add to their luggage at the time to distinguish it.

It takes no less than 40 hours to make a dial, and 38 colors are applied, one by one, with a brush – which has only a few extremely fine hairs – in successive touches. For each color, the whole thing is dried at 100°C for one hour. It is specified that several shades can be fired at the same time, but if they were to overflow, the whole thing would have to be started again.

Consult our technical sheets for Louis Vuitton watches.

Seel also:

Read also: